MIT Engineers Develop Ultrasound Stickers That Can See Inside the Body

Engineers from MIT have designed an adhesive patch that produces clear ultrasound images of heart, lungs, and other internal organs. In a paper appearing in Science, the engineers present the design for a new ultrasound sticker — a stamp-sized device that sticks to skin and can provide continuous ultrasound imaging of internal organs for 48 hours.

Engineers from MIT have designed an adhesive patch that produces clear ultrasound images of heart, lungs, and other internal organs. In a paper appearing in Science, the engineers present the design for a new ultrasound sticker — a stamp-sized device that sticks to skin and can provide continuous ultrasound imaging of internal organs for 48 hours.

The researchers applied the stickers to volunteers and showed the devices produced live, high-resolution images of major blood vessels and deeper organs such as the heart, lungs, and stomach. The stickers maintained a strong adhesion and captured changes in underlying organs as volunteers performed various activities, including sitting, standing, jogging, and biking.

The current design requires connecting the stickers to instruments that translate the reflected sound waves into images. The researchers point out that even in their current form, the stickers could have immediate applications: For instance, the devices could be applied to patients in the hospital, similar to heart-monitoring EKG stickers, and could continuously image internal organs without requiring a technician to hold a probe in place for long periods of time.

If the devices can be made to operate wirelessly – a goal the team is currently working toward – the ultrasound stickers could be made into wearable imaging products that patients could take home from a doctor’s office or even buy at a pharmacy.

“We envision a few patches adhered to different locations on the body, and the patches would communicate with your cellphone, where AI algorithms would analyze the images on demand,” says the study’s senior author, Xuanhe Zhao, professor of mechanical engineering and civil and environmental engineering at MIT. “We believe we’ve opened a new era of wearable imaging: With a few patches on your body, you could see your internal organs.”

The study also includes lead authors Chonghe Wang and Xiaoyu Chen, and co-authors Liu Wang, Mitsutoshi Makihata, and Tao Zhao at MIT, along with Hsiao-Chuan Liu of the Mayo Clinic in Rochester, Minnesota.

A sticky issue

In recent years, researchers have explored designs for stretchable ultrasound probes that would provide portable, low-profile imaging of internal organs. These designs gave a flexible array of tiny ultrasound transducers, the idea being that such a device would stretch and conform with a patient’s body.

But these experimental designs have produced low-resolution images, in part due to their stretch: In moving with the body, transducers shift location relative to each other, distorting the resulting image.

“Wearable ultrasound imaging tool would have huge potential in the future of clinical diagnosis. However, the resolution and imaging duration of existing ultrasound patches is relatively low, and they cannot image deep organs,” says Chonghe Wang, who is an MIT graduate student.

An inside look

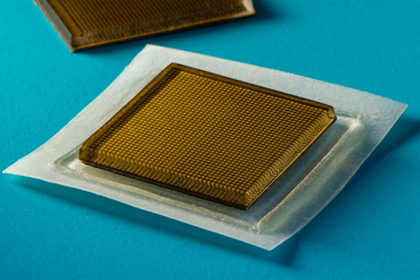

The MIT team’s new ultrasound sticker produces higher resolution images over a longer duration by pairing a stretchy adhesive layer with a rigid array of transducers. “This combination enables the device to conform to the skin while maintaining the relative location of transducers to generate clearer and more precise images.” Wang says.

The device’s adhesive layer is made from two thin layers of elastomer that encapsulate a middle layer of solid hydrogel, a mostly water-based material that easily transmits sound waves. Unlike traditional ultrasound gels, the MIT team’s hydrogel is elastic and stretchy.

“The elastomer prevents dehydration of hydrogel,” says Chen, an MIT postdoc. “Only when hydrogel is highly hydrated can acoustic waves penetrate effectively and give high-resolution imaging of internal organs.”

The bottom elastomer layer is designed to stick to skin, while the top layer adheres to a rigid array of transducers that the team also designed and fabricated. The entire ultrasound sticker measures about 2 square centimeters across, and 3 millimeters thick — about the area of a postage stamp.

The researchers ran the ultrasound sticker through a battery of tests with healthy volunteers, who wore the stickers on various parts of their bodies, including the neck, chest, abdomen, and arms. The stickers stayed attached to their skin, and produced clear images of underlying structures for up to 48 hours. During this time, volunteers performed a variety of activities in the lab, from sitting and standing, to jogging, biking, and lifting weights.

From the stickers’ images, the team was able to observe the changing diameter of major blood vessels when seated versus standing. The stickers also captured details of deeper organs, such as how the heart changes shape as it exerts during exercise. The researchers were also able to watch the stomach distend, then shrink back as volunteers drank then later passed juice out of their system. And as some volunteers lifted weights, the team could detect bright patterns in underlying muscles, signaling temporary microdamage.

“With imaging, we might be able to capture the moment in a workout before overuse, and stop before muscles become sore,” says Chen. “We do not know when that moment might be yet, but now we can provide imaging data that experts can interpret.”

The team is working to make the stickers function wirelessly. They are also developing software algorithms based on artificial intelligence that can better interpret and diagnose the stickers’ images. Then, Zhao envisions ultrasound stickers could be packaged and purchased by patients and consumers, and used not only to monitor various internal organs, but also the progression of tumors, as well as the development of fetuses in the womb.

“We imagine we could have a box of stickers, each designed to image a different location of the body,” Zhao says. “We believe this represents a breakthrough in wearable devices and medical imaging.”

This research was funded, in part, by MIT, the Defense Advanced Research Projects Agency, the National Science Foundation, the National Institutes of Health, and the U.S. Army Research Office through the Institute for Soldier Nanotechnologies at MIT.

Citation

MIT Engineers Develop Ultrasound Stickers That Can See Inside the Body. Appl Radiol.

July 29, 2022