Brookhaven Lab Updates Facility to Produce Actinium-225

Images

A recent upgrade to the medical isotope facilities at the US Department of Energy’s (DOE) Brookhaven National Laboratory now makes it possible to produce, purify and ship actinium-225 (Ac-225) ready for use directly from the Lab. Ac-225 is an isotope that shows great promise for treating cancer.

“This upgrade will streamline the overall production and distribution of Ac-225 to research centers by eliminating the need to ship material off site for final processing,” said Cathy Cutler, Director of Medical Isotope Research & Production (MIRP) at Brookhaven Lab.

The promise of Ac-225 stems from the way this radioactive isotope decays. It emits alpha particles, which can deliver a lethal punch to cancerous cells over a short distance. Attaching Ac-225 to molecules that target tumors could potentially kill cancer cells without harming surrounding tissue. Ac-225 can also be used to generate bismuth-213, another alpha-emitter.

Since 2014, MIRP scientists have been part of the DOE Isotope Program “Tri-Lab” effort to produce Ac-225 (and Ac-225/Bi-213 generators) so doctors can run clinical trials to test its efficacy. Using powerful proton accelerators, scientists at Brookhaven and Los Alamos National Laboratory irradiate targets made of thorium-232. The proton bombardment transforms some of the thorium atoms into actinium-225. Both Brookhaven and Los Alamos have been shipping their irradiated targets to Oak Ridge National Laboratory (ORNL), which has the facilities to extract and purify the isotope.

“Dmitri Medvedev of MIRP played a huge role in making this happen, both developing the targets we use at the Brookhaven Linac Isotope Producer (BLIP) and collaborating on the way we process alpha emitters with the Tri-Lab team,” Cutler said.

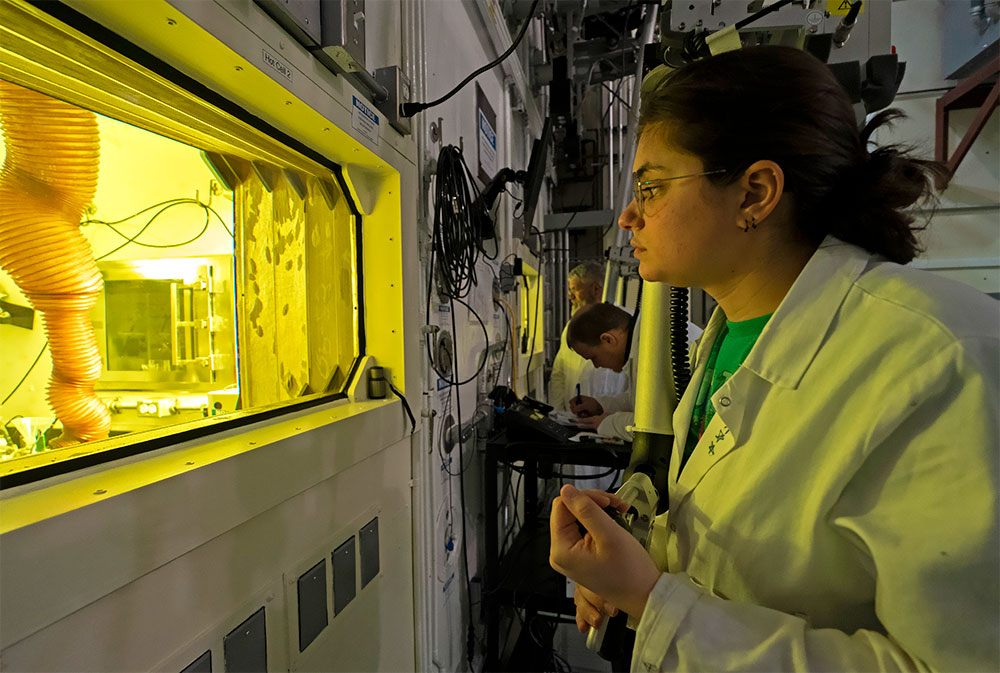

This Tri-Lab effort established reliable, routine Ac-225 production, and demonstrated that the process is scalable. But the availability of “hot-cell” space—the specialized labs and equipment needed for processing radioactive materials—limited how much Ac-225 could be made.

In 2018, the Brookhaven team and DOE worked out a solution. With an $8.5 million investment from the DOE Science Laboratories Infrastructure program, they began refurbishing an old metallurgical laboratory that had been dormant at Brookhaven since the 1990s. The renovation, led by Brian McCaffrey of Brookhaven Lab’s Facilities & Operations Directorate, included retrofitting the obsolete hot cell facility and labs to create a new All-Purpose (AP) Hot Cell facility to enhance Brookhaven’s Isotope Program processing capabilities.

“ORNL aided us in translating the process here. We also had to get special licensing and install new radiation-monitoring equipment,” Cutler said.

Brookhaven’s new AP hot cells, completed in March, have doubled the number of Ac-225 processing sites for DOE’s Isotope Program. This expanded processing capacity provides redundancy so Brookhaven and ORNL can serve as backups for each other.

There are clear benefits in having both target irradiation and hot cells for processing at one laboratory. It establishes a more efficient path for producing larger Ac-225 batch sizes by removing the logistical challenges inherent in involving multiple labs and transporting targets.

“Now we can irradiate the targets and process them right here at Brookhaven so that Ac-225 can be shipped directly to research centers,” Cutler said.