Via Christi Health: A case study in dose management

Reducing patient exposure to medical ionizing radiation in diagnostic procedures is a public health issue that has gained increased public awareness over the last several years. As a result, many hospitals are initiating dose management programs to address this important issue.

At Via Christi Health’s hospitals in Wichita, KS, U.S. Navy CAPT. (Ret.) Jerry Thomas, MS, DABR, CHP, DABSNM, has been spearheading a comprehensive dose management program that encompasses all ionizing radiation modalities — including digital radiography (DR). While much of the focus on reducing dose has historically been on computed tomography (CT), CAPT. Thomas and Alan Cebula, MS, diagnostic medical physicist, believe it’s just as important to manage dose for all diagnostic imaging modalities that use ionizing radiation.

“We have an obligation to our patients to obtain the highest quality diagnostic image at the lowest possible exposure,” CAPT.Thomas says. “Additionally, we need to determine an acceptable noise level so that noise in an image doesn’t interfere with the diagnostic process. This is important in all areas of medical imaging, not just in CT.”

Reducing dose starts with the detector

As part of the dose reduction initiative, in addition to the installed diagnostic X-ray DR imaging systems, Via Christi has replaced all chest and portable X-ray imaging systems with FDR D-EVO®, Fujifilm’s family of cesium iodide flat-panel detectors. Fujifilm’s patented Irradiated Side Sampling (ISS) technology is engineered to improve detective quantum efficiency (DQE) for clearer images at lower doses when compared to traditional design detectors. ISS positions its capture electronics (TFTs) at the irradiation side, in contrast to traditional detectors. This design suppresses scattering and attenuation of the captured x-ray beam, thereby producing sharper images at lower doses. ISS capture circuitry is designed to reduce dose and noise by as much as 10-20% when compared with other DR detectors and 30-75% when compared to CR.

Other built-in features, such as Dynamic Visualization™, helps Via Christi’s technologists further clarify imaging detail for higher diagnostic content. Plus, Fujifilm was one of the first companies to implement the IHE standard for EI/DI (Exposure Index/Deviation Index) dose tracking functionality.

“Fujifilm has been very helpful in supporting our software development and in configuring the devices,” says CAPT. Thomas. “The image quality and efficiency of the detector, (measured by DQE), is one of the primary tools for reducing dose to our patients.”

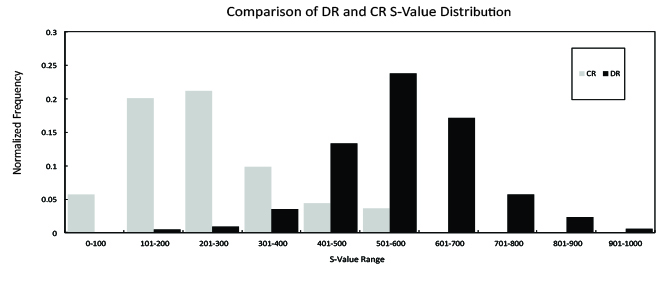

With the high DQE, there is real potential for dose reduction in all our imaging studies,” CAPT. Thomas adds. By moving from CR to DR with the FDR D-EVO detectors Via Christi now provides clearer x-ray images at lower doses. In fact, Cebula notes that Via Christi has reduced dose across DR studies by at least 50% compared to CR. However, the facility is going one step further with the development of a dose management quality control (QC) program.

“The tools we are developing are really the core of the QC program,” CAPT. Thomas explains. “We want to establish our own internal dose and deviation index for every exam, as well as conform to manufacturer recommended values. With Fujifilm’s assistance, we are developing a software program that allows us to capture user-specified DICOM data elements from the header data of acquired images.” These tools will be used to monitor and evaluate exposures from each of the different manufacturer’s DR products currently in use at Via Christi. “Our ultimate goal is to track and compare all diagnostic radiology exposures taken at each of our Wichita hospitals, clinics and free standing imaging centers, independently of the x-ray machine or DR vendor. CAPT. Thomas feels “This program can also be extended to older CR technology, with the limitation of not having automated mining of techniques used for the examination.”

According to Cebula, the software enables the user to examine exposure values for each FPD/detector across ten different DICOM tags, including exam type, date, patient name, technologist name, S value, exposure and deviation indices, DAP, kVp and mAs. “We are looking for trends in techniques and ensuring that the images taken are of diagnostic quality and consistent across technologists.”

This is accomplished through the continuous monitoring of “S” values and/or deviation index values from all fixed units and the exposure value of each portable detector. All analyses are performed automatically through the use of MATLAB, an image processing analysis tool. With this tool we plan on having a nearly “real time” analytical comparison of exposure trends at each of our Wichita facilities. CAPT. Thomas feels that the tool can be extended for use over the Via Christi Health enterprise throughout the State of Kansas.

“One of my long-term interests is to automatically analyze daily QC images from each DR x-ray unit for artifacts. This test should provide an “early warning” of spot damage to the DR detector – whether fixed or portable,” CAPT. Thomas says. “I want to identify damage to a detector prior to a radiologist calling me to review clinical images with artifacts. Additionally, variations in QC image SNR may be a useful indicator of an electronic malfunction in a detector or x-ray machine. We want to be proactive with equipment maintenance.” Evaluating protocols and workflow

In addition to evaluating the detector performance, Via Christi’s dose management program also takes into account the imaging protocols and the technologists’ workflow. In fact, Via Christi is one of the few hospitals in the country utilizing all the dose management capabilities that Fujifilm provides, including detector efficiency, monitoring and adapting protocols, and taking a proactive approach to maintenance.

In addition to refining the automated protocols provided by Fujifilm to fit the facility’s preferences, CAPT. Thomas and Cebula are working with technologists to help them identify practices that keep dose low. While using the same protocol each time is fundamental to quality low-dose imaging, there is variability in patient body habitus which requires modification of the fixed techniques, CAPT. Thomas explains. In training sessions, he shares the variations in “S” values for the same examination by shifts and departments—for example the fixed units in the radiology department versus the portables used in the ICU. Armed with this data, he can help the techs understand the impact of protocol modifications with a keen focus on keeping the mAs values as low as diagnostically possible.

Cebula also finds Fujifilm’s unique 1-Shot Phantom plus QC phantom to be a valuable tool for monitoring the detector characteristics. Its use has been expanded to all DR detectors at Via Christi. “The phantom and test protocol is very useful for comparing the performance of our DR detectors,” he says. “These tests show our FDR panels are very stable.”

CAPT. Thomas believes that stability and consistency also translate to higher confidence and accuracy in a radiologist’s reading. “I’m convinced with all my years in medical imaging, that consistency reduces reading fatigue. A fatigued radiologist has a higher probability of making a mistake, especially if the image is suboptimal (or non-diagnostic).”

With the dose management initiative and the QC program now taking flight, CAPT. Thomas feels that in one year he will have measurable performance and stability data on all DR systems across all imaging systems used by Via Christi in Wichita. The data set should be large enough for meaningful statistical trends in dose and technologist performance.

“We are keenly focused on our philosophy of providing the maximum benefit to risk ratio for our patients and our staff,” says Cebula. And it’s something that CAPT. Thomas believes he couldn’t achieve without the technology and support from Fujifilm.